A practical approach to supply chain vulnerability analysis using graph technology

COVID-19 makes us aware how vulnerable globally integrated supply chains in chemicals and process industries are. The impact of this crisis is severe because businesses are facing simultaneous supply and demand shocks, as well as disturbances or shutdowns in core operations. In stable times, companies typically – despite better knowledge – manage for excellence in individual functions such as procurement, operations, marketing. The current situation underpins the insufficiency of this approach as we see how closely everything is connected and intertwined in daily operations.

In crisis-mode companies put a lot of effort in risk assessment and mitigation to ensure business continuity: What if our suppliers run short? Where are we exposed to single sources? Which of our production facilities are system-critical? How to allocate products to customers in shortage situations? Those are typical questions elaborated in cross-functional task forces across the board. The answers are often difficult to obtain.

With our graph-based vulnerability analysis, we enable crisis teams by providing end-to-end transparency on their business. Within days, we help to identify and quantify risks in gate-to-gate supply chains and to assess mitigation measures.

Approach

1. Connect the dots

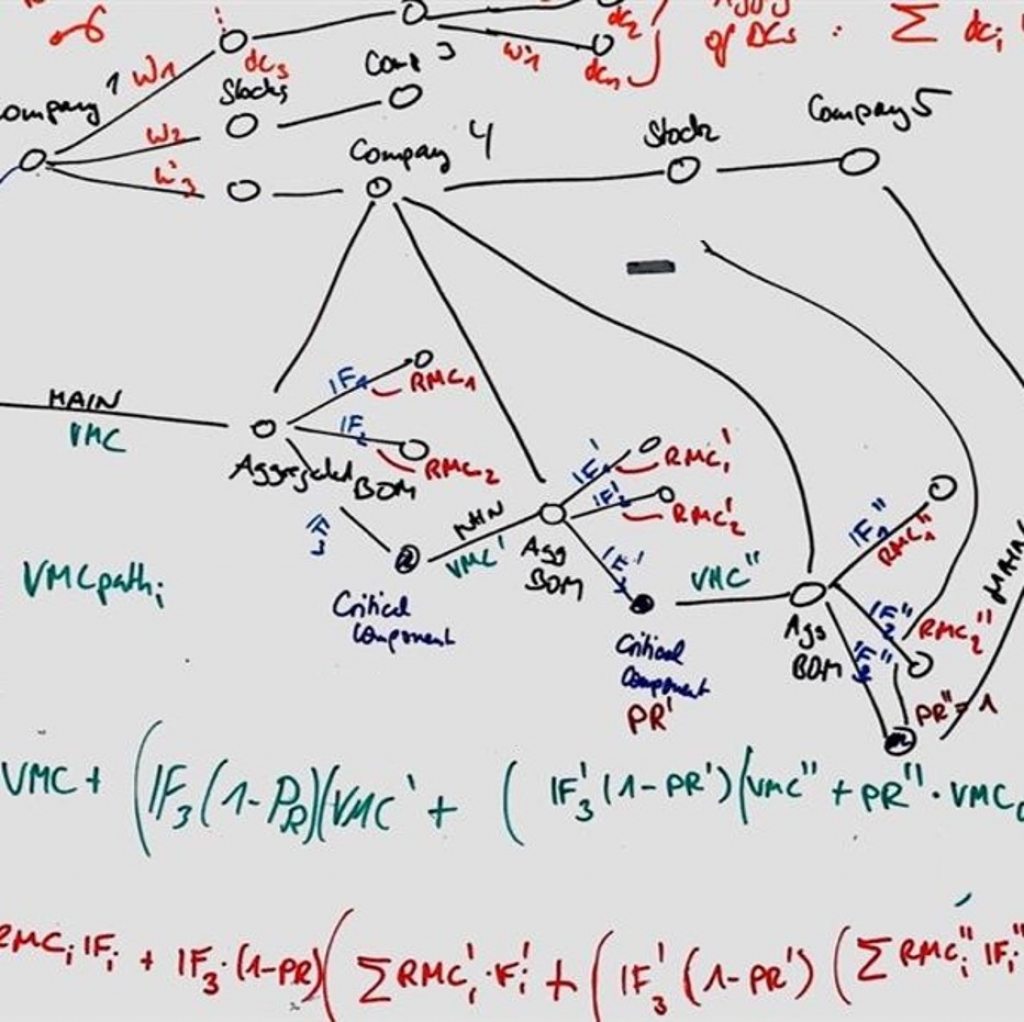

In a first step, we integrate data silos into a comprehensive model of a company’s end-to-end supply network. We link procurement data (suppliers, products, prices, etc.) with production recipes and network information with demand and sales data (customer, product mix, profitability, etc.). A key advantage of the graph-technology in use is the ability to integrate data, formats and protocols very fast and flexibly across sources. The scope and granularity of the model can be adjusted to your business needs and questions at hand.

2. Gain insights powered by the graph-model

Once the data model is set up, you will be able to run complex analysis on your supply chain. The nature of graph makes it simple to identify dependencies end-to-end. Frequently run analysis comprise:

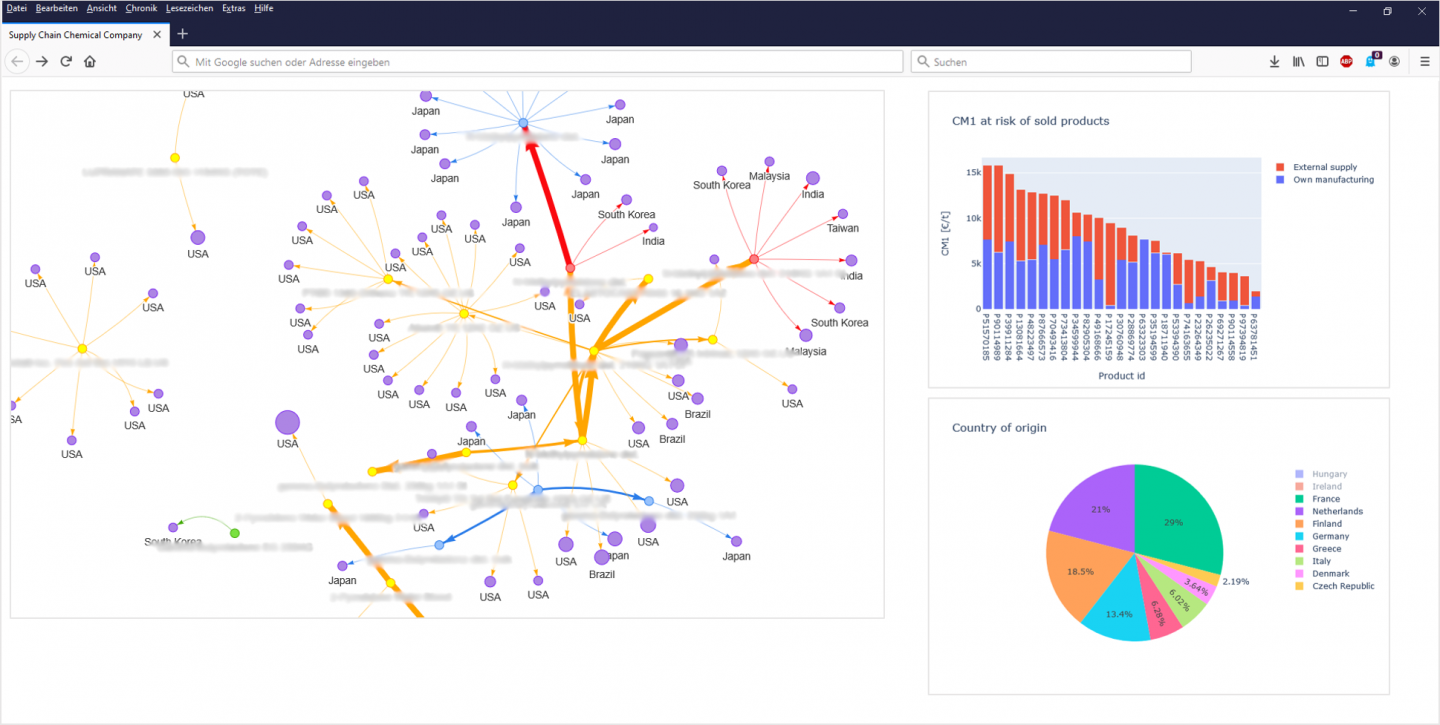

- CM1 at risk (for suppliers, materials, assets in value chains)

- Identification of critical suppliers across sites, regions, legal entities

- Prioritization of products and customers in allocation situations

- Value-based allocation of intermediates in integrated supply chains

- Identification of critical assets and infrastructure in the production network (across sites, regions, etc.)

3. Run scenarios for better decision making

The model enables you to run scenarios, to anticipate the potential impact of the crisis in an early stage and to prepare measures to increase the robustness of your supply chain. You may also use insights gained from scenario simulations for effective communication with suppliers, customers, authorities and employees.

Screenshot supply chain analytics tool for a chemical company

Fast and remote delivery

Our delivery model is suited for the current circumstances. We provide our services as a flexible extension to your crisis management team – remote, fast and in co-creation with your experts in business and IT. Within days you can be able to benefit from the power of the comprehensive analysis tool to find and manage vulnerabilities in your supply chain.

The database and related analysis tools create value far beyond the crisis.

Why not harness COVID-19 as catalyst for innovation?

Get in touch!

Please don't hesitate to get in touch with our experts for more information and an in-depth discussion